Sustainable biofuels solutions across Europe

& explore how we can help your business.

Looking to buy biofuel in Europe? Cargill is your trusted biofuel supplier offering biodiesel, HVO and bio-heating oil delivery and solutions tailored to meet the growing demand for low carbon fuels.

Why choose Cargill for your biofuel needs?

As a trusted provider of sustainable biofuel solutions, Cargill ensures consistent quality and supply through European-based production, helping reduce transport-related emissions. Our EU RED III compliant biofuels, made from renewable resources such as vegetable oils and waste residues, meet the highest standards across all applications —from transport to construction, and inland navigation to power generation.

We offer flexible supply options, tailored to your operational needs. As a committed partner, we work closely with customers on biofuels trials, supporting a smooth and effective transition to fossil free solutions, from initial testing to full-scale implementation.

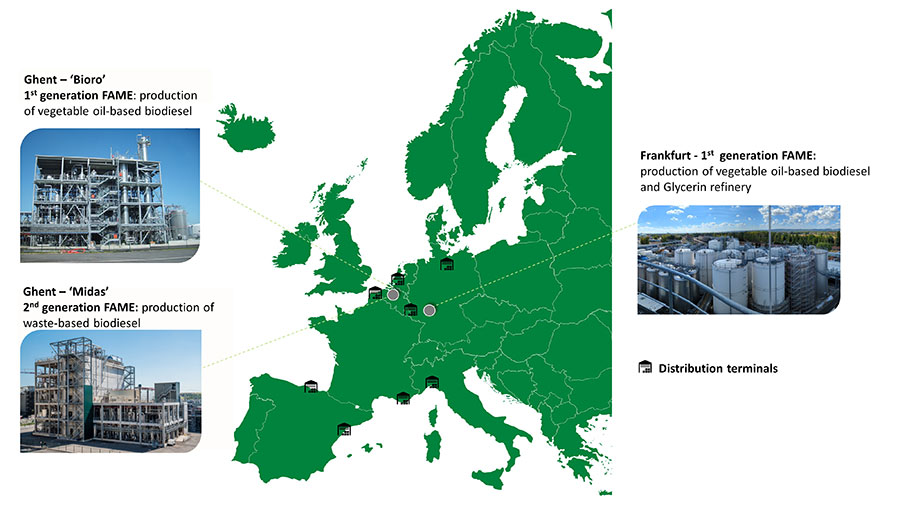

Explore Our Biodiesel Production Facilities in Europe

At Cargill, we are committed to advancing sustainable energy solutions across Europe. As a leading biofuel supplier in Europe, we focus on innovation and environmental responsibility to support global decarbonization goals.

Our production network ensures a reliable supply of high-quality, EU RED III compliant fuels, including FAME biodiesel, HVO, bio-heating oil, and bio-marine fuels. Whether you're seeking biofuel delivery or exploring low carbon fuel alternatives, Cargill provides scalable, flexible solutions for industries looking to decarbonize their operations.

Frankfurt, Germany facility

Since 2006, our Frankfurt Höchst facility has been a key hub for biofuel in Europe. Primarily processing rapeseed oil into FAME biodiesel, the plant also accommodates other oils and fats, offering flexibility in feedstock. An integrated glycerin refinery enhances efficiency of the site.

Ghent, Belgium facility

Cargill’s Ghent facility is a leader in renewable energy innovations. Operational since 2008, it is Belgium’s only fully integrated biodiesel production facility. In 2022, we additionally launched the MIDAS plant - one of Europe’s largest waste-to-biofuel operations. This advanced facility converts used cooking oil, animal fats, and edible oil residues into high-grade biodiesel, reinforcing our role as a key biofuel supplier.

How can Cargill biodiesel help you reach your decarbonization goals?

As Europe targets climate neutrality by 2050, decarbonizing industrial fleets and operations is more urgent than ever. Cargill® Bio100 is our flagship low carbon fuel, made entirely from vegetable oils or waste residues. This EU RED III compliant FAME biodiesel meets and exceeds EN14214 standards, offering:

- Compatibility with existing diesel engines

- Cost-effective emissions reduction

- Approval by leading engine manufacturers

Whether you're in transport, rail, shipping, mining, or power generation, Cargill® Bio100 is a reliable, high-quality solution for replacing fossil fuel.

Cargill is more than a biodiesel supplier—we’re a strategic partner in your sustainability journey. With production facilities in Belgium, Germany, and a robust logistics network, we ensure timely biodiesel delivery across Europe. Our portfolio includes both renewable diesel and biodiesel, giving you the flexibility to choose the right solution for your needs.

Cargill® Bio100 success stories

Sustainable Rail transport

Although rail is already recognized as an environmentally friendly mode of transport, many diesel locomotives still operate within the European rail network. Cargill and Lineas have successfully demonstrated that Cargill® Bio100, a readily available alternative to diesel, can be used in diesel locs on non-electrified railroad lines, such as those in Flemish ports. The adoption of Cargill® Bio100 has significantly reduced Lineas' emissions by 84% compared to conventional diesel.

Decarbonizing construction

Transitioning to electric construction equipment is a major trend in the construction industry, but off-grid sites often rely on generators for power. When these generators are fueled with fossil fuels to produce electricity for the electric equipment, the environmental benefits are undermined.Cargill® Bio100, approved by Algemene Bouw Maes, offers a solution by reducing emissions and avoiding fossil fuels in these generators, maintaining the green advantages of electric equipment even in remote locations.

Emission savings in logistics with Cargill® Bio100

Since 2020, Mervielde has been reducing CO2 emissions by using Cargill® Bio100 in their trucks. This renewable, locally produced fuel from Ghent can be used in Mervielde's vehicles without any modifications. Additionally, many trucking companies in France trust our non-hazardous energy source, which can immediately replace diesel fuel across entire truck fleets.

Fossil-free inland navigation

The Boreas, a barge of CFT Luxembourg (part of SOGESTRAN Group), has been successfully sailing with Cargill® Bio100 in Belgium for more than a year.

As a drop-in replacement for fossil fuels, Cargill® Bio100 is used without major engine modifications in the barge, ensuring smooth operation without any complications. The usage of Cargill® Bio100 in the barge has led to an impressive 70% reduction in greenhouse gas emissions, demonstrating that B100 biodiesel is a viable and effective solution for decarbonizing the inland navigation sector.

Frequently asked questions

What is the difference between biofuel and biodiesel?

Biofuel is a general term for liquid fuels made from renewable biological sources, such as plants or waste materials. Biodiesel is a specific type of biofuel that can be used as a direct replacement for conventional diesel. It is also known as FAME (Fatty Acid Methyl Ester) or B100 when used in its pure form.

Cargill offers both B100 biodiesel and HVO (Hydrotreated Vegetable Oil), another renewable diesel alternative that is chemically similar to fossil diesel.

How is biofuel different from fossil fuels?

Biofuels are derived from renewable sources whereas fossil fuels are derived from non-renewable sources that take millions of years to form and are rapidly depleted. The production of biofuels vs fossil fuels up to 95% greenhouse gases are saved. Compared to fossil fuels, the production and use of biofuels can result in up to 95% lower greenhouse gas emissions.

What is B100 biodiesel?

B100 refers to 100% biodiesel, meaning it contains no fossil diesel at all. In contrast, the diesel commonly available at fuel stations is typically B7, which includes up to 7% biodiesel blended with conventional diesel. B100 is made entirely from FAME (Fatty Acid Methyl Esters), making it a pure biodiesel option.

What is the difference between biodiesel and HVO?

Biodiesel and HVO (Hydrotreated Vegetable Oil) are both biofuels and made from similar feedstocks such as vegetable oils and waste oils. However, they differ in their production processes:

- Biodiesel is produced through a process called transesterification, resulting in FAME (Fatty Acid Methyl Esters).

- HVO is produced via hydrotreatment (hydrocracking), a process that removes oxygen, resulting in a fuel that is chemically similar to fossil diesel.

While both fuels are renewable, FAME biodiesel typically achieves higher greenhouse gas (GHG) savings compared to HVO when using the same feedstock. This is due to its less energy-intensive production process.

Is biodiesel compliant with EU RED III regulations?

Yes, biodiesel can be RED III compliant if it is made from approved feedstocks, achieves a minimum GHG savings, and is certified under an EU-recognized scheme.

How can my business switch to biodiesel fuel?

Cargill offers full support to businesses looking to transition from fossil fuels to biodiesel. The process typically begins with an assessment of engine and fleet compatibility. For transport companies, the first step is to check whether their vehicles can operate on biodiesel.

Once compatibility is confirmed, Cargill often supports a trial phase to test biodiesel performance in real-world conditions. We also assist with fuel storage solutions, including the provision of biodiesel tanks if needed.

Throughout the entire transition, Cargill provides hands-on support, from technical guidance during trials to tailored fuel supply solutions that meet your operational needs.

What emissions savings can I expect with Cargill® Bio100?

Cargill® Bio100 offers significant greenhouse gas (GHG) emissions savings, depending on the type of feedstock used:

- At least 60% GHG reduction when produced from vegetable oils.

- Up to 95% GHG reduction when derived from waste residues.

Our customers have the flexibility to choose the minimum GHG savings they would like to achieve.

What feedstocks are used in Cargill’s biodiesel production, Cargill® Bio100?

Cargill® Bio100 is produced using a variety of sustainable feedstocks, including:

- Vegetable oils, primarily rapeseed oil

- Waste oils, such as Used cooking oil, acid oils or fatty acids.

Our customers have the flexibility to choose their preferred feedstock based on sustainability goals or regulatory requirements. Individual selection or exclusion of specific feedstocks is also possible.

& explore how we can help your business.

Working with Cargill for EU Biodiesel

We combine production excellence and trading expertise to deliver integrated service customized to your needs.

Biodiesel Sustainability

We do the work and mitigate risks so you are free to focus on builfing your business.