Fermentation: nature’s original biotech

Key Takeways

- Fermentation has long been used to make everyday staples like yogurt, bread and soy sauce. Now, this ancient process is powering new innovations, enabling ingredient production that’s more scalable, reliable and resource efficient.

- As global demand for food, health products and sustainable materials continues to rise, fermentation offers a scalable solution for ingredient production to help meet those demands.

This article details what fermentation is, where it shows up in daily life and how we’re applying it to support innovation and strengthen our supply chains. It also highlights fermentation’s role in shaping the future of our food system.

What is fermentation?

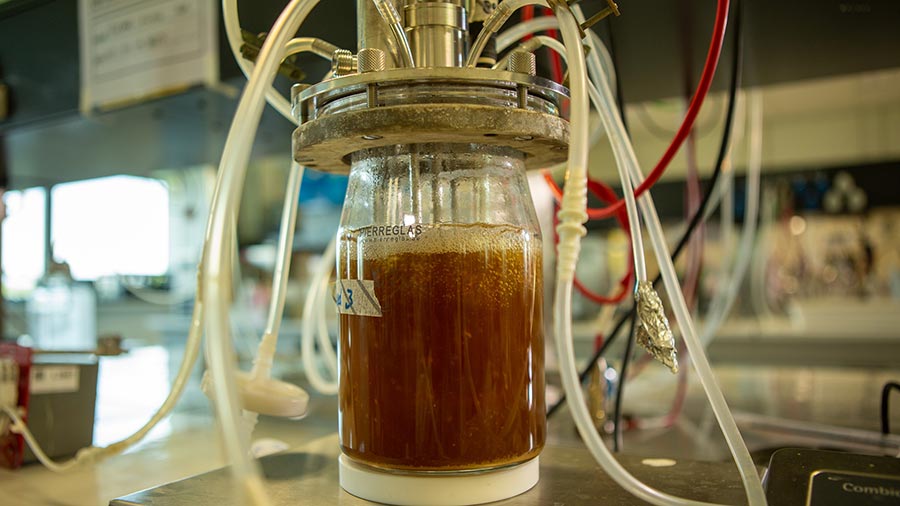

Fermentation is a natural process where microorganisms — like yeast, bacteria or fungi — convert simple sugars into other useful substances. It’s the science behind sourdough’s rise, yogurt’s tang and centuries of food preservation.

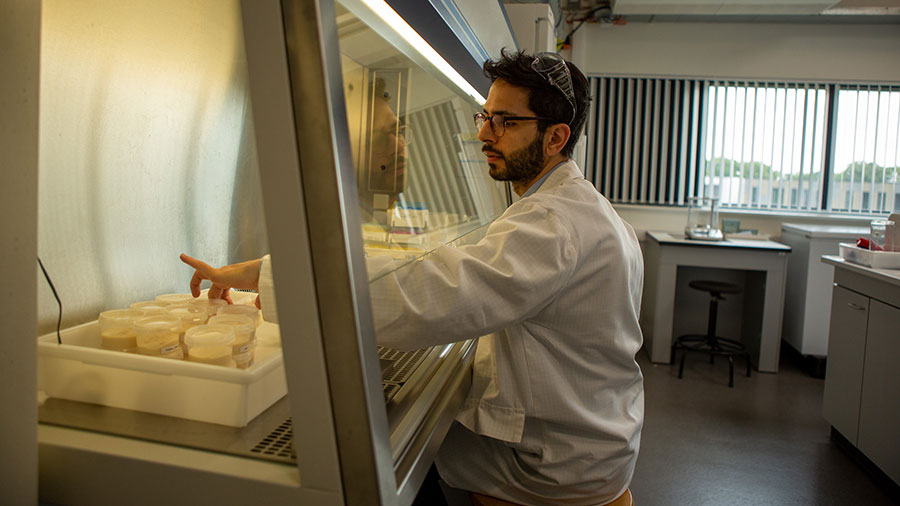

Today, advances in biotechnology allow scientists to guide microbes with precision. Known as precision fermentation, this technique can produce everything from food ingredients and proteins to vitamins and fibers, transforming how we make food, feed and everyday materials.

“Each cell is like its own powerful, renewable little manufacturing plant,” says Erin Marasco, a fermentation and biology research and development (R&D) expert at Cargill. “By using the natural metabolism of these cells, we can create all sorts of products that are beneficial to us.”

Fermentation in everyday life

Many people associate fermentation with traditional foods, but its role is much broader. Here are some places you’ll find it at work:

- Sour flavors in your snacks: Citric acid — widely used in sour candies and beverages — is commonly produced through fermentation.

- Better nutrition and immune support: Postbiotic ingredients like EpiCor® are made through fermentation and are used in dietary supplements to support gut health and immune function.

- Low- and no-calorie sweetness: Fermentation makes it possible to produce next-generation sweeteners like EverSweet® stevia and erythritol. By using engineered yeast to produce the sweetest stevia compounds without growing the plant, Cargill created a zero-calorie, scalable and lower-footprint solution that earned a 2023 Edison Award and was named a 2025 Global Good Award finalist for Game-Changing Innovation.

- Sustainable fibers and materials: Fermentation can turn corn sugar into molecules like bio-based BDO (1,4-butanediol), which is used to create stretchy fabrics for apparel from underwear to outerwear.

- Protein innovations: Mycoproteins, a fermented fungi, are gaining ground as an alternative protein, offering a meat-like texture.

- Healthy and productive animals: Diamond V® pioneered the use of microbial fermentation to create postbiotic feed additives that support immunity, gut health and overall productivity in cattle, poultry, swine and aquaculture. Over time, these science-backed fermentation solutions have also been adapted to support the health of companion animals, including dogs, cats and horses.

- Life-saving medicine: Fermentation helped revolutionize health care in the 20th century by supporting large-scale, affordable production of essential drugs like penicillin and insulin.

- Everyday kitchen staples: Fermentation creates the bold flavors in sriracha and soy sauce, the tangy fizz in kombucha, and the signature taste of sauerkraut and kimchi.

Why fermentation matters today

As global demand for food, health products and sustainable materials continues to rise, supply chains must become more resilient, flexible and resource efficient. Fermentation offers a scalable solution for ingredient production to help meet those demands.

“With fermentation, you're not dependent on a certain crop cycle, weather pattern or trade flow,” Erin says. “We can identify gaps in the food system and quickly scale up to fill them, often in ways that use fewer resources than traditional supply chains.”

Cargill’s leadership in fermentation

Cargill has built fermentation capabilities for more than 30 years, starting with citric acid in the 1990s and expanding through investment, partnership and innovation. Today, Cargill operates a global fermentation network with more than $2 billion invested in infrastructure and partnerships.

“We help customers bring scale to fermentation-derived products through proven, economical processes,” says Cordell Hardy, who leads Cargill’s deep sciences and core R&D teams. “It’s an exciting space and a critical tool for the future of food.”

Timeline: Cargill’s innovation and partnerships in fermentation over the years

- 1990: Citric acid – Cargill became an early adopter in combining large-scale fermentation with carbohydrate refining to improve efficiency and lower production costs.

- 1992: Ethanol – Cargill integrated ethanol plants with biorefineries to boost resilience and help weather market swings better than stand-alone facilities.

- 1996: Erythritol – Cargill was one of the first companies to produce erythritol via fermentation, replacing chemical hydrogenation to offer a zero-calorie sweetener alternative.

- 1997: Itaconic acid – Cargill adapted existing fermentation assets for new, value-added uses.

- 2001: Lactic acid – Cargill advanced microbial strains to scale lactic acid production with fewer inputs and a smaller environmental footprint.

- 2017: EpiCor® – Cargill acquired Diamond V and expanded EpiCor®, a yeast fermentation-derived postbiotic that supports immune function and gut health in both animal and human nutrition.

- 2018: EverSweet® – Cargill entered a joint venture with Royal DSM to develop and scale a precision fermentation process to produce EverSweet, a zero-calorie sweetener delivering a sugar-like taste without bitterness.

- 2021: QIRA® – Cargill partnered with HELM to launch Qore and introduced QIRA®, a bio-based spandex ingredient made from renewable sources.

- 2025: Cargill and Qore opened a $300 million facility in Iowa to produce QIRA® at scale using corn grown by local farmers.

What is the future of fermentation?

The future of fermentation isn’t just about what we can make; it’s about what we can make possible. With better tools and deeper insights, this natural process is unlocking new ways to nourish people and the planet.

Fermentation gives us more flexibility in how and where we produce food. It brings speed, precision and reliability to a food system that must adapt quickly to change. At Cargill, we’re building on decades of experience to help bring these solutions to life with trusted partners around the world. As demand grows, fermentation will play a central role in making the food system more resilient, responsive and ready for what’s next.

“There’s so much potential ahead as we combine biology, data and design,” Cordell says. “Fermentation is a natural process, but we’re just beginning to explore what it can do.”

Your questions about fermentation, answered

Is fermentation natural or synthetic?

Fermentation is a natural biological process where microbes like yeast or bacteria convert sugars into useful compounds like acids, alcohols or gases. Even when guided with modern tools like genetic engineering, the process still relies on the natural metabolic activity of these organisms, similar to how farmers have long improved crops through selective breeding.

What are common foods made through fermentation?

Fermentation is behind many familiar foods and drinks, including bread, yogurt, beer, wine, miso, soy sauce, kombucha, kimchi, sauerkraut, pickles and sriracha. These items rely on microorganisms to enhance flavor, texture, preservation and even nutritional value.

How does fermentation benefit human health?

Fermentation has been used safely for centuries and is linked to gut and immune health through fermented foods like yogurt, kimchi and kefir. Today, fermentation also powers the production of postbiotic ingredients, vitamins and probiotics used in dietary supplements and functional foods to support overall wellness.

What is precision fermentation?

Precision fermentation uses biotechnology to guide microbes in producing specific, high-value ingredients, like sweeteners, proteins, or vitamins, with more control and consistency. It’s still fermentation at its core, just enhanced by modern tools that help scale production and expand what’s possible.

What are non-food uses of fermentation?

Beyond food, fermentation is used to make materials like bio-based plastics, spandex fibers and biodegradable packaging. It also plays a critical role in pharmaceuticals, helping produce at scale essential medicines like insulin and penicillin.

What is Cargill's role in fermentation?

Cargill has more than 30 years of experience in fermentation, investing over $2 billion in infrastructure and partnerships. From citric acid and EverSweet® stevia sweetener to Diamond V® feed ingredients and QIRA® bio-based fibers, Cargill uses fermentation to create better food, feed and material solutions for a changing world.

How is fermentation used in sustainable production?

Fermentation enables more resource-efficient production by using sugars from renewable feedstocks like corn instead of fossil fuels. It allows ingredient manufacturing to happen closer to where raw materials are grown, which can reduce transportation, emissions and supply chain risks.

Innovation at Cargill

From idea to impact, we innovate to reimagine what’s possible.